SPOT LIGHT

Cylindrical shape with integral driver housing.

Glare-Free effect providing comfort to the eyes

Interchangeable Beam Lens for various lighting effect

High efficiency heat sink

-

SUMI

Originally meaning simply “ink,” is also the origin of SHODO, an ancient Japanese practice of artistic hand writing.

UNITY’s R&D applies this traditional mindset into the design of the lighting fixture. -

DESIGN

To minimize the presence of the fixture itself and still achieve a constant lighting effect.

-

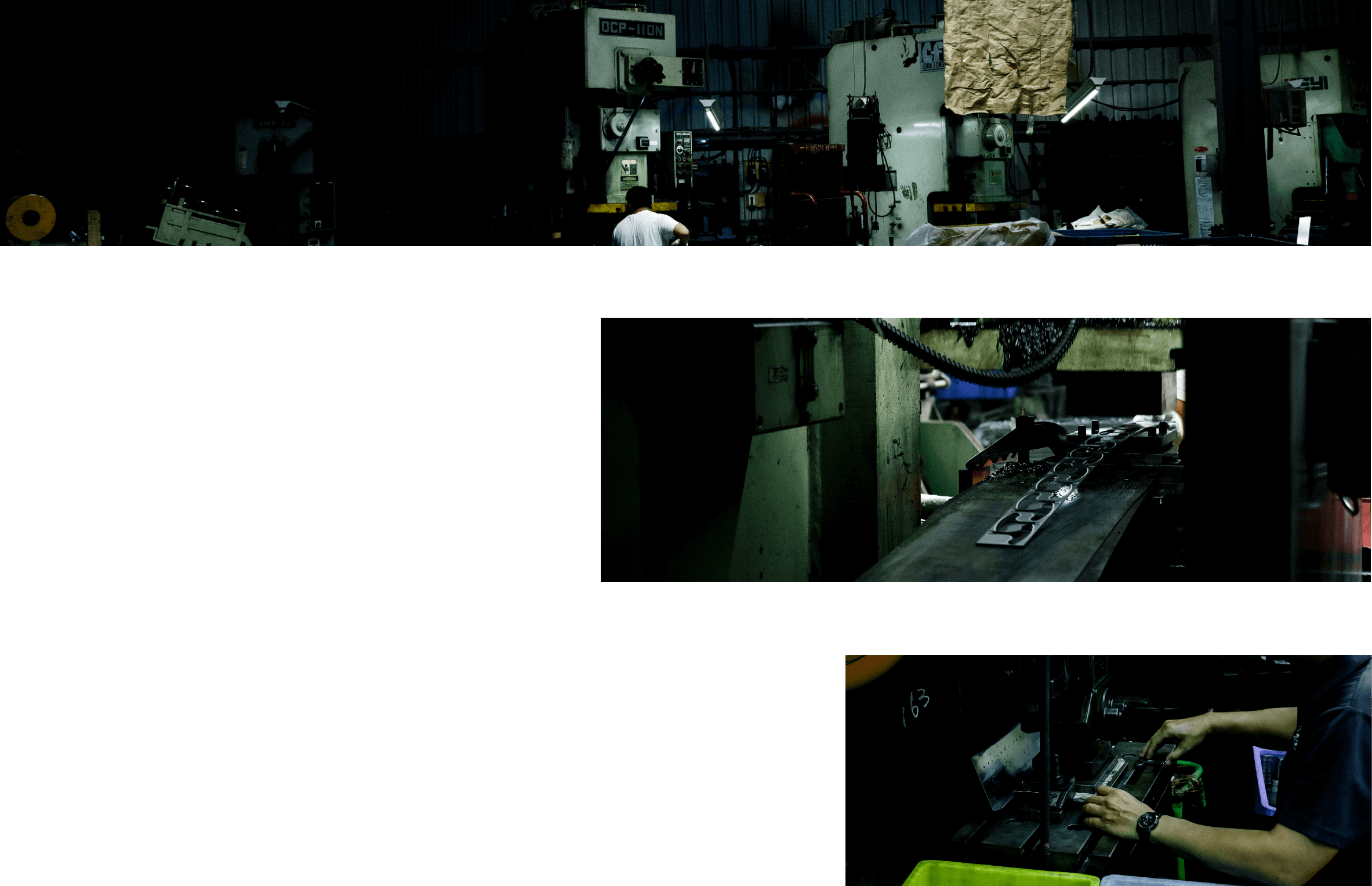

OEM/ODM

Beautiful transparent lighting to match different environments.

GLARELESS DOWN LIGHT

Adjustable

Glare-Free effect providing comfort to the eyes

Interchangeable Beam Lens for various lighting effect

High efficiency heat sink

GLARELESS DOWN LIGHT

SURFACE MOUNT

Our new surface mount fixture achieves the same glare-free effect as our Glare less downlight series.

It makes an indispensable glare cut contribution to the overall impression of the architectural space.

Can also add a rail adapter which can be installed to usual lighting rails.